ARCA-IPW

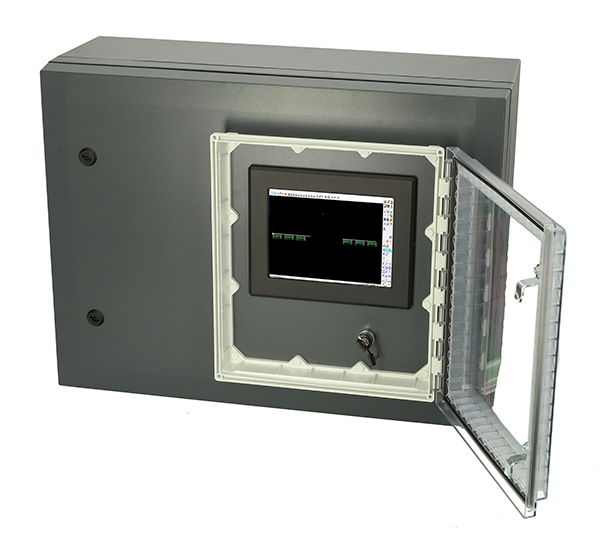

With a secure low profile, continuous hinge design, and sleek integrated quarter turn locks, the ARCA Instrument Protection Window (IPW) minimizes access to where security and safety are needed.

Available in five JIC sizes, the Instrument Protection Window is a UL / cUL-listed, NEMA type 4X rated HMI cover. The IPW can be mounted on any manufacturer’s enclosure to provide safe and secure access to underlying components and instruments. Instrument Protection Windows are available with opaque or transparent covers and various locking options.

Once locked, the dual Formed-In-Place polyurethane gasketing maintains a dry, dust-free environment.

Material: Polycarbonate

NEMA Type: NEMA 4, 4X, 6, 6P, 12, 12K and 13

Size Range (H x W x D) in: 10 x 8 x 3.31 D → 18 x 16 x 3.31 D

Size Range (H x W x D) mm: 250 x 200 x 88 D → 460 x 452 x 88 D

ARCA-IPW Products:

Showing products whose dimensions are within +/- 10% of the search query.

About ARCA-IPW HMI Covers

- UL-listed, NEMA 4X rated, low-profile continuous hinge.

- Overlapping cover for strength & increased gasket protection.

- Large viewing area transparent covers.

- Multiple locking options.

- Opaque & transparent covers.

- Robotically laid dual PUR gasket.

- Bolt-on installation.

The IPW provides an easy-to-install, secure HMI access point to any enclosure or flat surface with its high ingress and impact protection (IP66 and IK09) and NEMA 4X ratings.

About ARCA-IPW Human Machine Interface Covers

-

UL-listed, NEMA 4X rated, low-profile continuous hinge.

-

Overlapping cover for strength & increased gasket protection.

-

Large viewing area transparent covers.

-

Multiple locking options.

-

Opaque & transparent covers.

-

Robotically laid dual PUR gasket.

-

Bolt-on installation.

The IPW provides an easy-to-install, secure HMI access point to any enclosure or flat surface with its high ingress and impact protection (IP66 and IK09) and NEMA 4X ratings. It facilitates the integration of various electronic controls and equipment, making it ideal for modern machine controls and factory automation.

HMI Enclosures

HMI enclosures are designed to provide a safe and secure environment for Human Machine Interface (HMI) applications across various industries. These enclosures are engineered to protect sensitive systems from harsh industrial conditions, including moisture, chemicals, dirt, and temperature fluctuations. Available in a range of sizes and materials, such as steel, aluminum, and stainless steel, HMI enclosures are tailored to meet specific application requirements. Whether in a factory setting or a commercial environment, these enclosures ensure that HMI systems remain operational and protected, enhancing the longevity and reliability of the equipment.

Materials and Construction

HMI enclosures are constructed from high-quality materials to ensure durability and corrosion resistance. Steel enclosures are crafted from robust 14-gauge steel, providing a sturdy and reliable option for many industrial applications. Aluminum enclosures, known for their lightweight and corrosion-resistant properties, offer an excellent balance of strength and ease of handling. For environments that demand the highest levels of cleanliness and resistance to harsh conditions, stainless steel enclosures are the ideal choice, particularly in food processing and pharmaceutical industries. These rugged constructions are designed to withstand the rigors of industrial environments, offering long-lasting protection for HMI components.

Applications and Industries

HMI enclosures find their use in a wide array of industries, including industrial, commercial, and residential applications. They are essential in scenarios where HMI components, such as push buttons, touchscreens, and panel PCs, need protection from harsh environments. Additionally, HMI enclosures are crucial in applications requiring ergonomic and comfortable working heights, such as machine control and factory automation. These enclosures are compatible with modular suspension arm systems, allowing for easy repositioning and adjustment of HMI components, thereby enhancing operational efficiency and user comfort.

Design and Customization

HMI enclosures are designed with easy installation and customization in mind. Featuring removable front plates, these enclosures simplify the installation of HMI components. Optional door panels can be mounted as needed, and cutout options are available to meet specific requirements. The design also considers ergonomic factors, providing comfortable working heights that improve operator visibility and comfort. Customization options are extensive, including positioning handles, access panels, keyboard sections, trays, and pivot mounts, allowing users to configure the enclosure to their precise needs. This flexibility ensures that the enclosures can be tailored to fit any environment or specification, making them a versatile solution for various applications.